Mechanical Series

Float and displacer switches for any application.

Internationally recognized

50+ years of service

Unsurpassed durability

With 50+ years in production, the Delta Controls Series 700 mechanical switches are the industry standard for quality engineered mechanical level switches. With service up to 20,000 psig and 1100 °F, the Delta mechanical switches are available in a wide range of materials, process connections, and configurations to provide reliable service in even the most challenging applications. For process conditions beyond the limits of standard instrumentation, Delta has an engineered mechanical solution.

Showing all 15 results

-

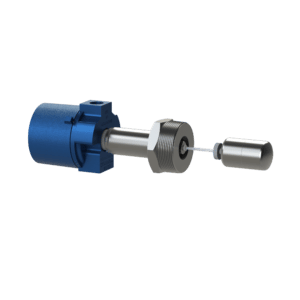

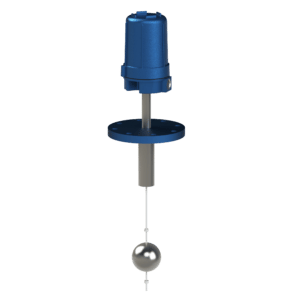

Model 709

Float Switch, Top Inserted, Single Point

Learn More » -

Model 710

Float Switch, Top Inserted, Two Point

Learn More » -

Model 711

Float Switch, Top Inserted, Two Point, Wide Separation

Learn More » -

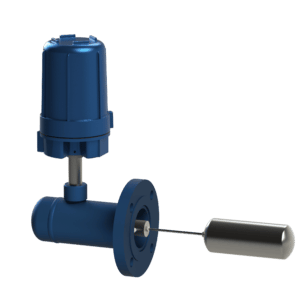

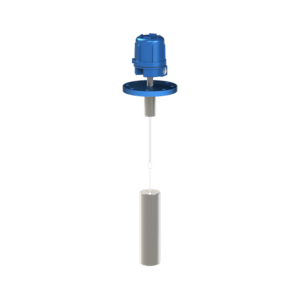

Model 715

Displacer Switch, Top Inserted, Single Point

Learn More » -

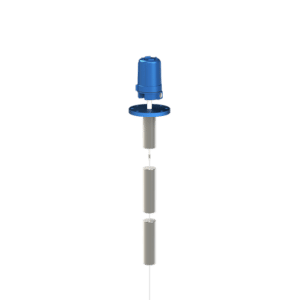

Model 716

Displacer Switch, Top Inserted, Two Point

Learn More » -

Model 717

Displacer Switch, Top Inserted, Three Point

Learn More » -

Model 735

Float Switch, Side Inserted, Single Point

Learn More » -

Model 740

Float Switch, Side Inserted, Two Point

Learn More » -

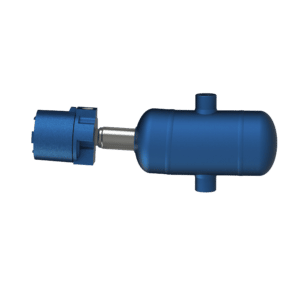

Model 750

Float Switch, External Cage, Horizontal

Learn More » -

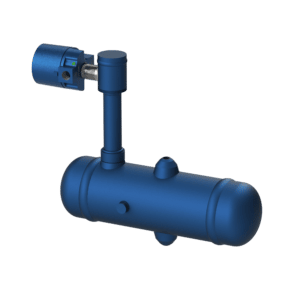

Model 760

Float Switch, External Cage, Vertical

Learn More » -

Model 762

Displacer Switch, External Cage, Vertical, High Pressure

Learn More » -

Model 763

Float Switch, External Cage, Horizontal, High Temperature and Pressure, Steam Service

Learn More » -

Model 765

Float Switch, External Cage, Vertical, Two Point

Learn More » -

Model 767

Float Switch, External Cage, Vertical, Two Point, Wide Spacing

Learn More » -

Model 770

Float Switch, External Cage, Vertical, multipoint

Learn More »