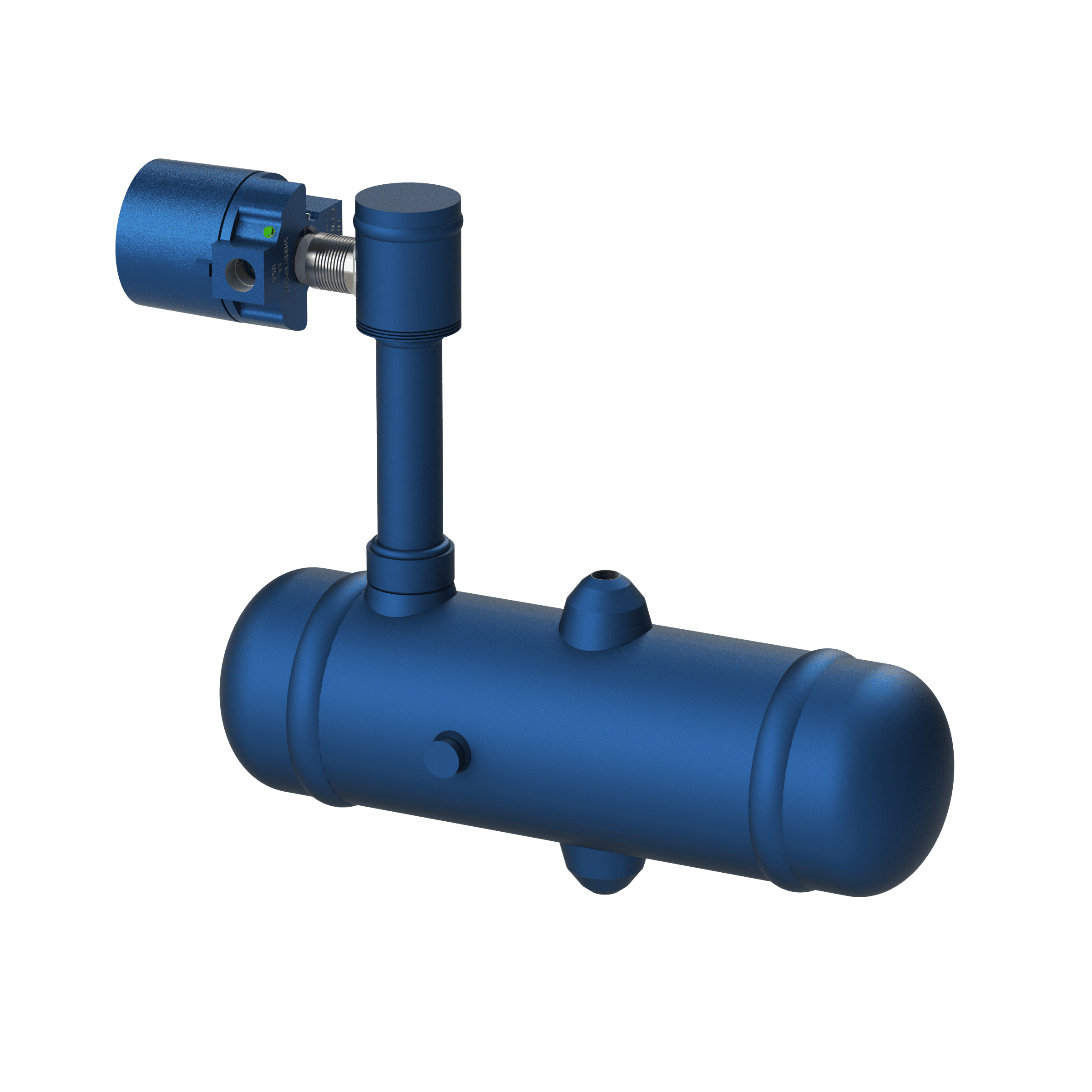

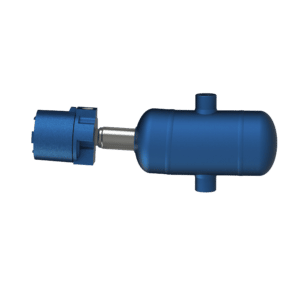

Float Switch, External Cage, Horizontal, High Temperature and Pressure, Steam Service

The Delta Controls Model 763 Float Switch is specially intended for the tough applications found in boiler houses and heating facilities. The 763 is typically used in steam drum level and drip leg services and similar environments.

Various element styles are utilized to produce the most reliable operation under the specific service conditions. Dual magnets are standard in all models providing reliable and positive switching. They also make the units immune to the vibration-induced false alarms and shutdowns.

The 763 condensate level switch produces a switching action when a liquid level passes a selected elevation. The sensing element is mounted in an external cage. An external cage is utilized to minimize the effects of turbulence, boiling, and splashing on the measurement. The cage can also be valved off from the process, cooled and depressurized which allows for inspection, testing, maintenance, etc.

The output signal from the 763 consists of one or more heavy SPDT dry contacts. The unit has a strong heavy wall displacer sensing element. The weight of this element is partially offset by a pivoted counterweight. The displacer net weight is strictly a function of the earth’s gravity. Switch action is unaffected by process temperature and other variables. This design allows it to work reliably at temperatures in excess of 1500 °F (815 °C).

The 763 is highly reliable and operates at high temperatures and pressures. Only a single weight which is kept in position by a pivot shaft, moves. Reliable magnet lines of force penetrate the cage wall and connect up to the output switch.

Features

- Single alarm point

- High pressure service

- Reliable operation in steam condensate applications

- Simple, robust design

Specifications

- Wetted Materials: 316 Stainless Steel, carbon steel

- Switch Action: Single point alarm

- Specific Gravity: 0.30 to 2.40

- Interface Differential: 0.1 min

- Temperature: -350 °F to +1100 °F (-212 °C to +593 °C)

- Pressure:-15 psig to 6000 psig (-1 bar to +414 °C)

- Orientation:Top/Bottom

- Threaded Process Connection: 1.0 in FPT, 1.0 in to 4.0 in MPT

- Flanged Process Connection: 1.0 in to 8.0 in

- Butt or Socket Welded Process Connection: 1.0 in

- Flange Rating: ≤ 1500 lb ANSI flanges, Grayloc® hub, DIN or JIS equivalents

Certifications & Approvals

- Third Party Listed by CSA NRTL/C (USA and Canada) Class I, Division 1, Groups B, C and D; Class II, Division 1, Groups E, F and G; Class III,Division 1 Class I, Zone 1, Ex d IIB+H2 Class I, Zone 1, AEx d IIB+H2

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)

- Process fluid or material name*

- Process fluid or material specific gravity

- Maximum process temperature

- Maximum process pressure