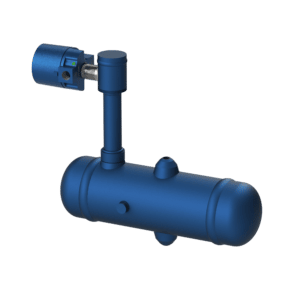

Displacer Switch, External Cage, Vertical, High Pressure

The Delta Controls Model 762 Displacer Switch provides high temperature and high pressure output switching at one elevation of a varying liquid level. The unit’s primary element mounted outside the process vessel. The external cage design is utilized to minimize process turbulence effects and so that the level alarm may be valved off from the process vessel. It can then be depressurized for testing and maintenance without disturbing the operation of the process. The output of the unit consists of a switching action at a preset liquid level elevation. The liquid level rises and the displacer lifts the attractor in front of the switch station magnet. This external magnet pulls in and the output switch is actuated. Decreasing liquid level moves the displacer assembly downwards. The output switch deactuates when the attractor is pulled out of the switch station’s magnetic field.

The switch station is mounted external to the barrier tube and is isolated from the process liquid. It is equipped with a magnet whose lines of force pass through the non-magnetic barrier tube. The magnet is pulled in against the outside of the tube and actuates the microswitch(s) when the attractor is lifted into the magnetic field inside the tube. This unit utilizes thick wall displacers for sensing elements. The support spring offsets most of the displacer weight so that liquid buoyancy requirements are minimized. It is designed for very high pressure services, even those with low specific gravities.

Features

- Mechanical simplicity produces maximum reliability

- Designed in accordance with ANSI B31

- Low specific gravity operation, optional pressure to 20 000 psig

- Interface detection at high pressures

- Insensitive to high frequency vibration

- No seals to leak, magnetically coupled

Specifications

- Wetted Materials: 3304 Stainless Steel, 316 Stainless Steel, carbon steel

- Switch Action: Single point alarm

- Specific Gravity: 0.40 to 2.40

- Temperature: -100 °F to +800 °F (-73 °C to +427 °C)

- Pressure: -15 psig to 20 000 psig (-1 bar to +1400 bar)

- Optional Drain: 1.0 in NPT

- Orientation: Side/Bottom, Side/Side, Side/Side/Drain

- Socket Welded Process Connection:1.0 in

- Threaded Process Connection:1.0 in FPT to 2.0 FPT

- Flanged Process Connection:1.0 in to 2.0 in

- Flange Rating: ≤ 2500 lb ANSI flanges or Greyloc® hub DIN or JIS equivalents

Certifications & Approvals

- Third Party Listed by CSA NRTL/C (USA and Canada) Class I, Division 1, Groups B, C and D; Class II, Division 1, Groups E, F and G; Class III, Division 1 Class I, Zone 1, Ex d IIB+H2 Class I, Zone 1, AEx d IIB+H2

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)

- Process fluid or material name*

- Process fluid or material specific gravity

- Maximum process temperature

- Maximum process pressure