Float Switch, External Cage, Horizontal

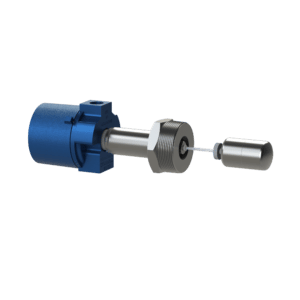

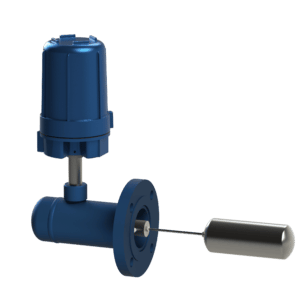

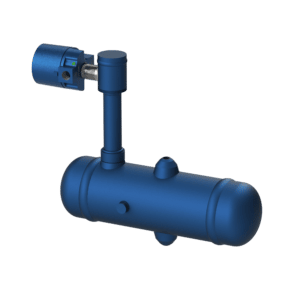

The Delta Controls Model 750 Float Switch utilizes a balanced horizontal element design for point level detection. Model 750 is suitable for high temperature and pressure. The sensing elements can be made solid for high pressures, better reliability, and corrosion resistance. A float is held in a horizontal position by a counterweight pivot mechanism. As the liquid level rises, the sensing element is moved vertically up. This movement results in short stroke rotary motion which carries the drive magnet into the field of the switch station magnet.

The vertical dimension has a nominal requirement. Its dual magnet positive switching action is reliable as well as insensitive to vibration and shock. This modern design has significant advantages over vertically rising float design. The straight through piping is efficient, lowers installation costs, and switch point can be set to a new elevation without cutting on the process vessel.

The switch magnet is pushed against the side of the sealing tube and the output switch is actuated. When the liquid level falls, the sensing element moves down with it. The drive magnet is rotated back through the magnet fields; the switch magnet is repulsed, the switch returns to its original position, and the output switch deactuates. The dual opposed magnet design provides snap action of the switch mechanism; immunity from vibration, and greatly improved reliability.

Features

- One alarm point

- Small, vertical mounting

- External cage mounted outside process vessel

- Float type leveling switch

- Balanced horizontal element design

Specifications

- Wetted Materials: 316 Stainless Steel, carbon steel

- Switch Action: Single point alarm

- Specific Gravity: 0.50 to 2.40

- Temperature Range: -200 °F to +1100 °F (-129 °C to +593 °C)

- Pressure Range: -15 psig to +1750 psig (-1 bar to +120.7 bar)

- Orientation: Top/Bottom

- Butt or Socket Weld: 1.0 in

- Threaded Process Connection: 1.0 in FPT 1.0 in to 4.0 in MPT

- Flanged Process Connection: 1.0 in to 8.0 in

- Flange Rating: ≤ 1500 lb ANSI flanges, Grayloc® hub, DIN or JIS equivalents

Certifications & Approvals

- Third Party Listed by CSA NRTL/C (USA and Canada) Class I, Division 1, Groups B, C and D; Class II, Division 1, Groups E, F and G; Class III, Division 1 Class I, Zone 1, Ex d IIB+H2 Class I, Zone 1, AEx d IIB+H2

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)

- Process fluid or material name*

- Process fluid or material specific gravity

- Maximum process temperature

- Maximum process pressure

- Upper and lower materials required for interface service