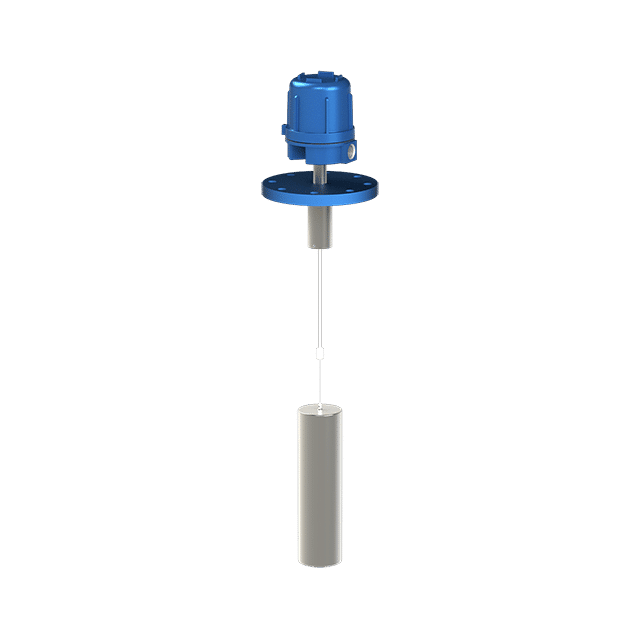

Displacer Switch, Top Inserted, Single Point

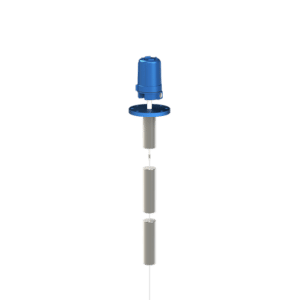

The Model 715 Top Displacer Switch provides activation of a single switch station as the liquid level surface rises past the elevation at which the displacer has been positioned. Similarly, the switch station is deactivated as the liquid level falls below the displacer.

A displacer, which is more dense than the process liquid, is supported by a spring. The length of the spring is proportional to the amount of weight that it supports—the less the weight, the longer the spring will be. When liquid covers a displacer the amount of weight, equal to the weight of the process liquid displaced, is removed from the spring and is supported by the process liquid. The spring length proportionally increases and the attractor moves into the switch station’s magnetic field. The magnet is pulled against the outside of the sealing tube, and the output switch is activated.

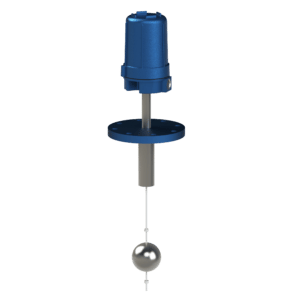

Similarly, when the process fluid uncovers the displacer, the liquid weight equal to the volume of the displacer is transferred back to the spring. The length of the spring decreases to its original length and the attractor is pulled out of the magnetic field. The magnet is pulled back to its original position and the output switch deactuates. For floating roof type tanks, the 715 may be used to detect the position of the roof.

The 715 may be equipped with a lead weight instead of a displacer. When positioned on the top of a floating roof tank, the roof lifts the weight as the 715 rises, triggers an alarm switch to warn that the roof has reached the limit.

Features

- Single switch station activation

- High or low alarm for liquid level or interface position

- Suitable for floating roof type tanks

- Optional brass displacer

- Optional ground level checker

Specifications

- Wetted Materials: 316 Stainless Steel, lead, brass, carbon steel

- Insertion (Below Process Connection): ≤ 50 ft (16 m) max

- Switch Action: Single point alarm

- Specific Gravity: 0.50 to 2.0

- Temperature Range:-20 °F to +500 °F (-29 °C to +260 °C)

- Pressure Range: -15 psig to +2200 psig (-1 bar to +151.7 bar)

- Threaded Process Connection:2.0 in to 3.0 in NPT

- Flanged Process Connection:4.0 in to 8.0 in

- Flange Rating: ≤ 300 lb ANSI flanges or Grayloc® hub DIN or JIS equivalents

Certifications & Approvals

- Third Party Listed by CSA NRTL/C (USA and Canada) Class I, Division 1, Groups B, C and D; Class II, Division 1, Groups E, F and G; Class III, Division 1 Class I, Zone 1, Ex d IIB+H2 Class I, Zone 1, AEx d IIB+H2

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)

- Process fluid or material name*

- Process fluid or material specific gravity

- Maximum process temperature

- Maximum process pressure