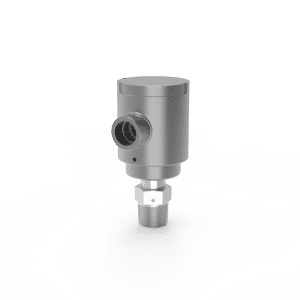

Pressure Transmitter, Modular Electronics, Sanitary Service

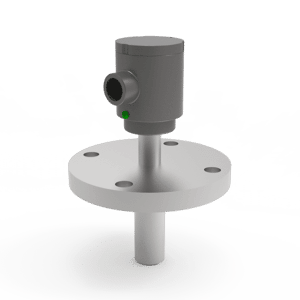

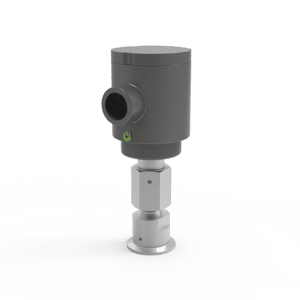

The Delta Controls Model 572 Pressure Transmitter is designed specifically for food, pharmaceutical, and ultraclean applications. The 572 consists of a potted electronic module in a housing which is mounted with a modular pressure sensor as a packaged assembly. The wetted sensor is constructed of 316 Stainless Steel. The body is polished and free from crevices, cracks, and voids that can harbor contaminants. The back of the sensor is usually vented to atmosphere to compensate for barometric pressure changes.

Easily clean Model 572 by disassembling and manually washing, or clean and sterilized in place. The 572 is used as a liquid level transmitter in vented tanks. The pressure at the bottom of a vented tank containing liquid is linearly proportional to the height and density of the liquid.

Features

- Two-wire loop powered 4-20 mAD dc signal

- Fits with a Tri Clamp, APC, and other sanitary connections

- Suitable for ultraclean water service

- Suitable for CIP/SIP service

- Removable electronic module

- Polished body is basic, polished housing optional

- Zero and Span pots for field recalibration

- Spark and power surge protection

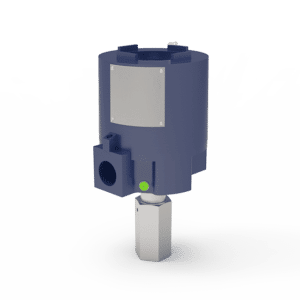

- Optional LCD display

- Optional HART® communication protocol compliant

- Maintenance free operation

Specifications

- Technology: Silicon strain gauge

- Supply Power: 13 DCV to 35 DCV 2-wire loop powered

- Output Signal :4-20 mA, isolated

- Maximum Loop Impedance: 550 Ω at 24 DCV, 1100 Ω at 35 DCV

- Over Pressure:2X range or 35 psi min (+2.5 bar) 3X range or 1000 psi min (+70 bar)

- Process Temperature: -20 °F to +220 °F (-29 °C to +104 °C)

- Electronics Temperature: -20 °F to +185 °F (-29 °C to +85 °C)

- Compensated Temperature: +30 °F to +130 °F (-1 °C to +55 °C) (higher available)

- Accuracy:≥ ± 0.5% FS

- Thermal Error:± 0.02% FS/ °F max

- Barometric Effect: None

- Communication: Device menus, Optional HART® communication protocol

Certifications & Approvals

- Explosion-proof Housing Option: Third Party Listed by CSA NRTL/C (USA and Canada) Class I, Groups B, C and D; Class II, Groups E, F and G; Class III; Encl 4X:

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Factory calibration: custom range or full-scale

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)