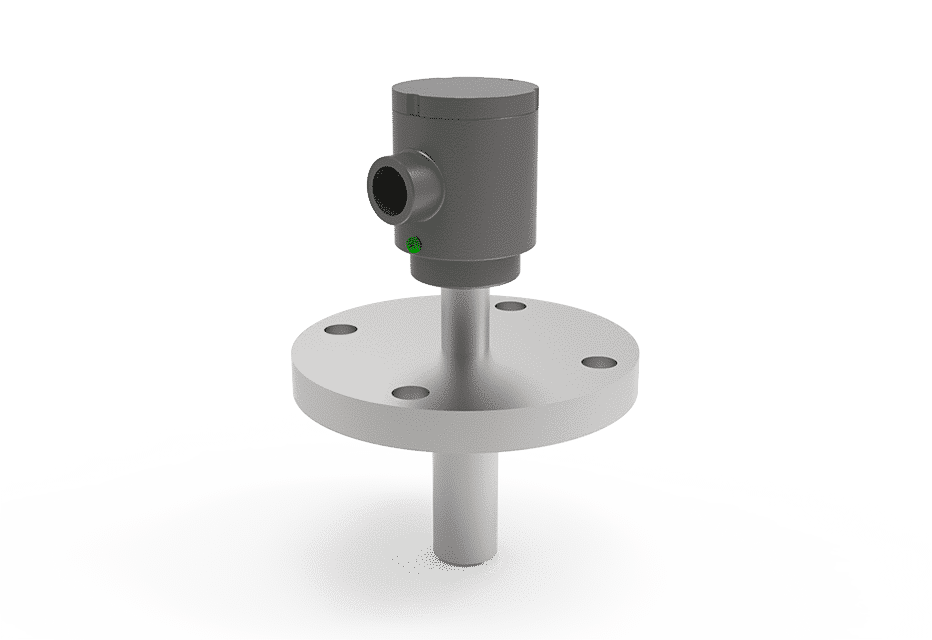

Pressure Transmitter, Modular Electronics, Extended Face

The Delta Controls Model 563 Pressure Transmitter consists of a potted electronic module and a flush diaphragm pressure sensor packaged in a one piece unit. The sensor is equipped with an oil-filled 316 Stainless Steel or Hastelloy® C-276 diaphragm that isolates the strain gauge bridge from the process liquid or gas. The back of the diaphragm is vented to atmosphere to compensate for barometric pressure changes. A desiccant filter or isolation bladder prevents moisture accumulation in the vent tube.

The 563 is side or bottom mounted on a vessel and measures the pressure exerted on the sensor face by the liquid head. The pressure at the bottom of a vented tank containing fluid is linearly proportional to the height and density of the fluid.

The flush diaphragm is intended for measurement of dirty or high solids content products that might easily plug the small openings and tubing connections of typical transmitters. The extended diaphragm is used to gain access to the inside of a tank to avoid being plugged by deposits and sediment. The extended face allows the sensor to be located inside the vessel to insure that solids do not cause measurement errors. Model 563 is useful for pressure measurement of pipelines handling liquids with entrained solids. The sensor has no recessed cavities that would collect particles or become plugged.

Features

- 4-20 mA 2-wire loop powered

- Suitable for difficult liquids and slurries

- NPT, ANSI, DIN, or JIS Process Connection

- NPT, ANSI, DIN, or JIS Process Connection

- 12 inches of water to 500 psig (+1 bar to +34.5 bar)

- Surge protection

- Unaffected by process coating

- HART® communication protocol compliant, optional

- Maintenance free operation

Specifications

- Technology: Silicon strain gauge

- Supply Power: 13 DCV to 35 DCV 2-wire loop powered

- Output: 4-20 mA dc isolated

- Maximum Loop Impedance: 550 Ω at 24 DCV, 1100 Ωat 35 DCV

- Over Pressure: 2X range or 35 psi min (+2.5 bar) 3X range or 1000 psi min (+70 bar)

- Process Temperature: -20 °F to +220 °F (-29 °C to 104 °C)

- Electronics Temperature: -20 °F to +180 °F (-29 °F to +82 °C)

- Compensated Temperature: +30 °F to +130 °F (-1 °C to +54 °C)

- Accuracy: ≥ 0.5% FS

- Thermal Error: 0.02% FS/°F max

- Communication: Device menus, Optional HART® protocol compliant

Certifications & Approvals

- Explosion-proof Housing Option: Third Party Listed by CSA NRTL/C (USA and Canada) Class I, Groups B, C and D; Class II, Groups E, F and G; Class III; Encl 4X:

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Factory calibration: custom range or full-scale

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)