Pressure Transmitter, Large Diaphragm, Integral Electronics

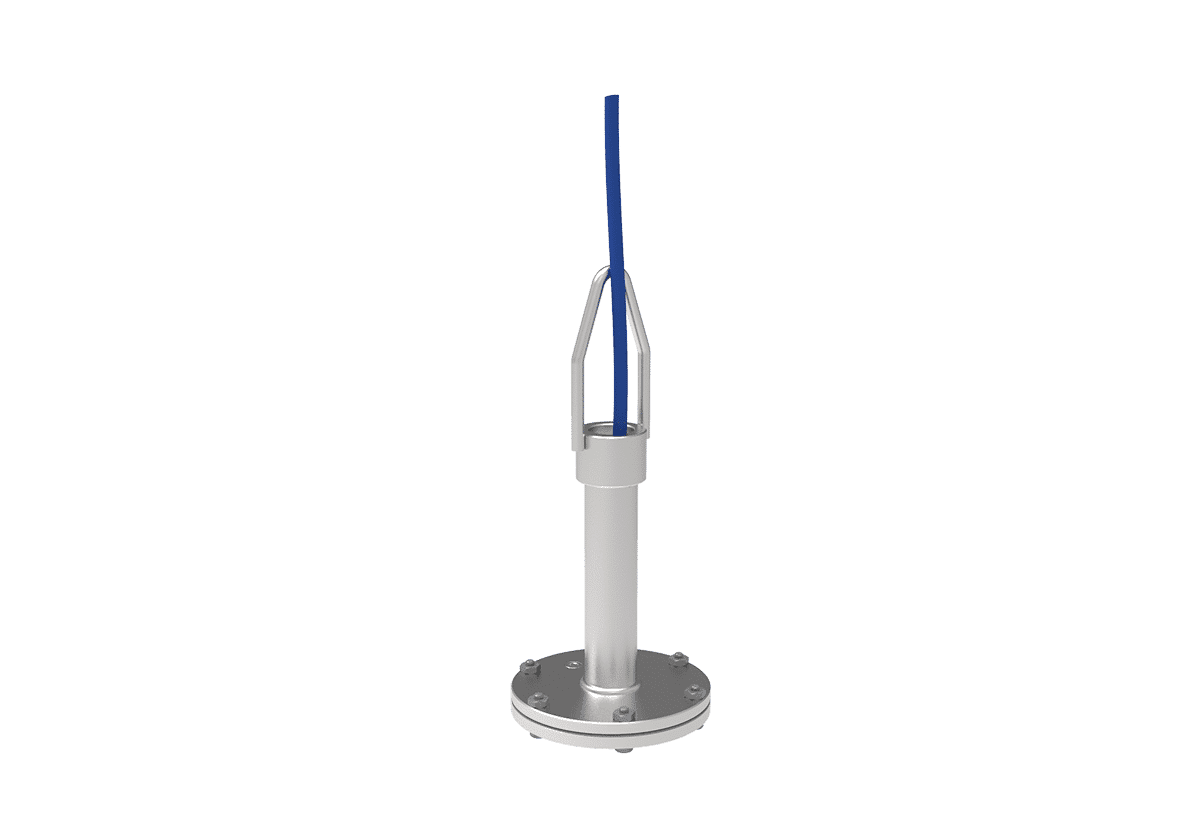

The Delta Controls Model 565 Pressure Transmitter is a completely self-contained head pressure type level transmitter. When installed in a lift station, sump, basin, or other containment, the strain gauge sensor detects the liquid level as a function of the height and density of the liquid above it. The electronics and calibration adjustments are contained inside the body with the strain gauge sensor, and the cable is sealed to the transmitter body. It is of modular construction.

The open diaphragm cannot become plugged or rendered inoperable by liquids with high solids content such as sewage, wastewater, and slurries. The diaphragm is fabricated from tough EPDM rubber, and is coupled to the strain gauge through a nontoxic fill. The face has superior resistance to damage from gravel, and other moving solids. Its large three inch active face size, and its smooth outer surface makes it extremely durable and reliable in harsh services. A vent tube connected directly to the sensor compensates for atmospheric pressure changes. The optional desiccant filter, or isolation bladder, prevents condensation in the vent tube. No refilling or maintenance is required for the bladder.

Features

- Flexible isolator for wastewater and slurries

- Large, rugged EPDM diaphragm

- Supported by rigid pipe or flexible cable

- 4-20 mA, 2-wire loop powered

- 316 Stainless Steel body

- PVC or TEF cable jacket

- Surge protection

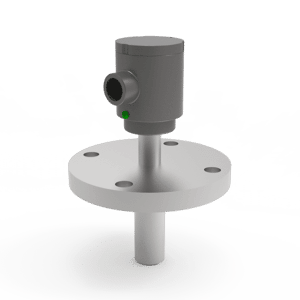

- Optional cable junction box with isolation bladder

- Reliable, no maintenance

- HART® protocol compliant

Specifications

- Technology: Silicon strain gauge

- Supply Power: 13 DCV to 35 DCV 2-wire loop powered

- Output Signal: 4-20 mA isolated

- Maximum Loop Impedance: 550 Ω at 24 DCV, 1100 Ω at 35 DCV

- Protective Devices:Transient suppressors and lightning arrestors

- Liquid Temperature: -20 °F to +220 °F (-29 °C to +104 °C)

- Electronics Temperature: -20 °F to +180 °F (-29 °C to +82 °C)

- Compensated Temperature:+30 °F to +130 °F (-1 °C to +54 °C)

- Accuracy: ≥ +0.5% FS

- Thermal Error: +0.015% FS/ ºF max

- Barometric Effects:None

- Over Pressure:2X range or 35 psi min (+2.5 bar)

- Communication:Device menus, HART communication protocol

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Factory calibration: custom range or full-scale

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)