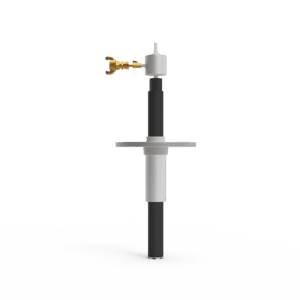

Thermocouple, Sulfur Processing Service, Unpurged, ATEX, IECEx

The Delta Controls Model HTV Unpurged Thermocouple is designed for the primary purpose of reliably protecting a vessel and its refractory lining from excessive temperatures. The HTV is intended for installations without access to a purge system.

The design of the HTV is the result of attention to detail and more than 50 years of experience in the sulfur recovery industry. The thermocouple junction is isolated from the process gases by using a permeation resistant thermowell constructed of monocrystalline sapphire. The patent-pending QSeal™ design prevents trace amounts of process gases from leaking past the seals and accumulating inside the thermowell. In the event of thermowell breakage, multiple redundant seals prevent the release of process gases.

For most applications, the Model HTX purged thermocouple is preferred as it offers the highest reliability and best track record of any thermocouple in sulfur processing service. However, Model HTV provides a highly reliable alternative for installations unable to accommodate the Model HTX’s installation requirements.

The HTV is built to meet each customer’s specific installation requirements such as thermocouple type, operating temperatures, nozzle size, insertion length, and materials of construction. The HTV assembly is furnished complete with all necessary installation components. Installation tools are available, and recommended, to accurately produce the refractory borehole in the correct size and alignment needed for the thermocouple assembly.

Features

- Patent pending QSeal™ technology

- Unpurged thermocouple for sulfur processing services

- Unique thermocouple element protection system

- Wide range of available process connections

- Streamlined installation and maintenance

- Designed to work accurately in sulfur service long after other unpurged thermocouple designs fail

- Dual thermowells provide robust corrosion protection

Specifications

- Thermocouple Types: B, R, S (others available)

- Body Material: Stainless steel

- Trim, Bolting, and Seats: Stainless steel

- Housing Material: Aluminum or 316 Stainless Steel

- Primary Thermowell Material: Silicon carbide

- Secondary Thermowell Material: Monocrystalline sapphire

- Process Connection: ANSI 1.5 in to 3.0 in MPT, ANSI 1.5 in to 6.0 in (other classes, sizes, types, ratings available)

- Working Pressure: 150 psig (10.3 bar) at 500 °F (260 °C)

- Working Temperature: 0 °F to 3100 °F (-18 °C to 1704 °C)

- Required Accessories:

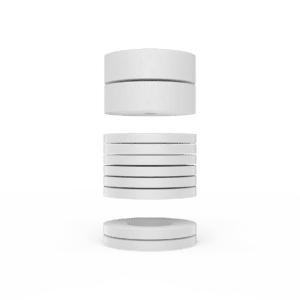

Model HNP Nozzle Packing Kit

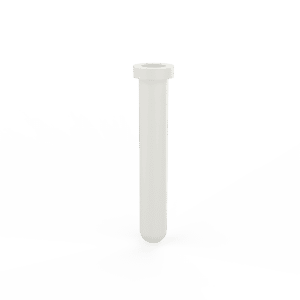

Model HRW Refractory Well* - Optional Accessories:

Model HRS Nozzle Refractory Stop

Model TEW Thermocouple Extension Leadwire

Model HRM Casting Mandrel

Field Training, Consultation and Assistance

Certifications & Approvals

- 70131733 Ex db IIB + H2 T3 Gb Class I Zone 1, AEx db IIB + H2 T3 Gb

- Sira 18ATEX1044x II 2G, Ex db IIB + H2 T3 Gb Ta = -4 °F to +158 °F (-20 °C to +70 °C)

- IECEx SIR 18.0012x Ex db IIB + H2 T3 Gb

- EAC TR CU 012/2011

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation & testing packages (if required)

- Installation Details

Nozzle inside diameter

Shell thickness

Nozzle inside height

Refractory thickness

Nozzle angle from vertical

Related Downloads

- CSA Certificate of Compliance

- EU Declaration of Conformity

- IECEx Certificate of Conformity

- Application Data Form – Large Nozzles

- Application Data Form – Small Nozzles

- HTV IOM