Capacitance Level Switch, Multipoint, Two or Four DPDT Relays

The Delta Controls Model 107 multipoint Capacitance Switch uses RF admittance technology to produce switching action when a material level crosses the switchpoint. The interface position between two liquids with different dielectric constants is accurately detected, including with cloudy interface conditions. One of the liquids should be nonconductive. Model 107 is not sensitive to specific gravity (SPG) variations.

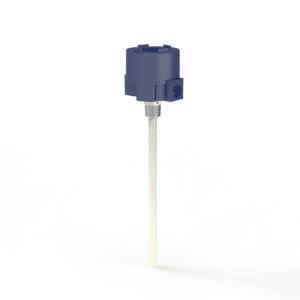

Many probe configurations are available. The electronics module can be remotely mounted.

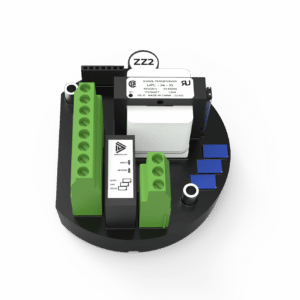

107 features digital circuitry, pushbutton setup, LCD display, and is potted for severe environments. Simple, two point calibration allows calibration and recalibration to occur without emptying tank. On/off elevation is separately selectable for each of the two 5 A DPDT relays.

Features

- RF admittance type circuitry

- Insensitive to process coatings and buildup

- LCD direct reading level display

- Simple, two point calibration without emptying tank

- Direct or reverse calibrated

- Built-in self-diagnostics

- Integral or remote mounted electronics housing

- Process temperature -350 °F to +750 °F (-210 °C to 435 °C)

- Adjustable time delay of 1 to 60 seconds

- Epoxy sealed electronics module

- Pressure Rating: Vacuum to 10 000 psig (-1 bar to +700 bar)

- Application specific probe shapes, styles, configurations, and process connections

- Wetted materials include stainless steel, PTFE, Kynar®, Monel, and ceramic

Specifications

- Level range (Independently Programmable): On and off set points along entire probe length, 0 pF to 8000 pF

- Number of Relays: Two 5 A at 250 VAC DPDT

- Time Delay: 0.25 s to 30 s

- Basic Supply Voltage: 120 - 240 VAC (optional 24 DVC)

- Ambient Operating Temperature: -40 °F to +180 °F (-40 °C to +85 °C)

- Temperature Effect (0 °F to 150 °F): ± 0.25 SU Typically < 0.25 in (6 mm) (water)

- Housing: 4X hose-proof, 6 submersible, Class 1, Division 1, Groups BCD, EFG explosion-proof option

- Housing Material : Aluminum, PVC, stainless steel

Certifications & Approvals

- Housing Option: Third Party Listed by CSA NRTL/C (USA and Canada) Class I, Groups B, C and D; Class II, Groups E, F and G; Class III; Encl 4X

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation & testing packages (if required, refer to Additional Resources in the product catalog)