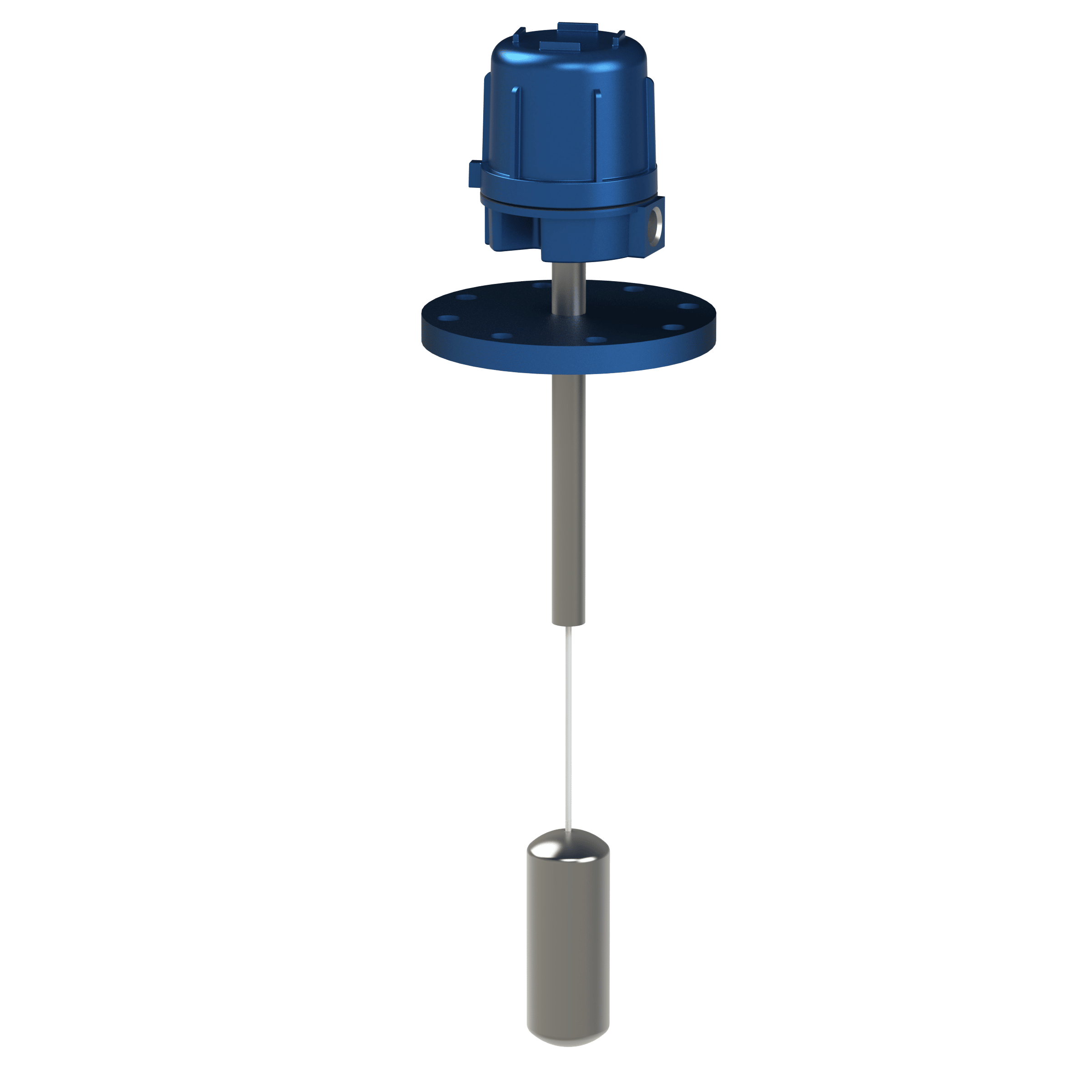

Float Switch, Top Inserted, Single Point

The Delta Controls Model 709 Float Switch is a simple mechanical device which is highly reliable over long periods of time. An alarm switch-type action is provided as the liquid level surface passes through the elevation where the sensing float has been positioned. The sensing float is attached to a vertical shaft, which can move up and down. Lifting the float causes the output switch station to activate. The switch station is on the outside of a solid, non-magnetic pipe wall. This isolation eliminates the possibility of leaking seals and flex tube failures, which are problems in many other designs.

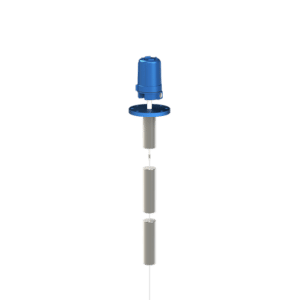

The 709 is commonly used for high level alarms and shutdown on tanks. The float may be extended down into the tank to 12 feet. It provides switch action as far as 12 feet down into the tank and allows the 709 to be used as a low-level alarm.

Unlike most competitive switches, the 709 float rod guide is always located just three inches above the float and thus avoids the need for any type of ‘stilling well.’ Moderate swirling or fluid motion will not damage the 709. A permanent magnet is attached to the actuating lever of the switch. As the liquid level rises, the float is carried upwards and the attractor is carried into the field of the magnet. The magnet is attracted and pulled against the wall of the sealing tube. This movement actuates the output switch. When the liquid level falls, the float drops, the attractor is pulled out of the field of the magnet and the output switch returns to its original position.

Features

- Simple mechanical device

- High reliability

- Sensing float

- High level alarms

- Float guide always located 3 inches above float

- Non-magnetic, heavy-duty sealing tube

Specifications

- Wetted Materials: 316 Stainless Steel, carbon steel

- Insertion (Below Process Connection): ≤ 12 ft (3.5 m)

- Switch Action: Single point alarm

- Sensing Element: 316 Stainless Steel

- Specific Gravity: 0.4 to 2.40

- Temperature: -150 °F to +750 °F (-101 °C to +399 °C)

- Pressure: -15 psig to +730 psig (-1 bar to +50 bar)

- Threaded Process Connection: 1 in to 4 in MPT

- Flanged Process Connection: 2 in to 8 in

- Flange Rating: ≤ 300 lb ANSI, Grayloc® hub, DIN, JIS equivalents

Certifications & Approvals

- Third Party Listed by CSA NRTL/C (USA and Canada) Class I, Division 1, Groups B, C and D; Class II, Division 1, Groups E, F and G; Class III, Division 1 Class I, Zone 1, Ex d IIB+H2 Class I, Zone 1, AEx d IIB+H2

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)

- Process fluid or material name*

- Process fluid or material specific gravity

- Maximum process temperature

- Maximum process pressure

- Upper and lower materials required for interface service