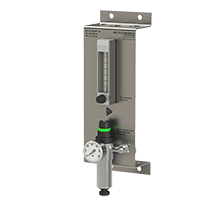

Flush Gas Station, For Use with HIR Pyrometer

The Delta Controls Model HFI Flush Gas Station provides a filtered purge gas across the process side of the Model HIR lens glass to reduce particulates from accumulating on lens. The HFI provides a single place at the reactor where the operator can regularly monitor and verify proper operation of the flush gas stream.

The HFI insures long-term temperature measurement reliability by flushing dust and ash from the pyrometer lens window. It is typically mounted on a vertical surface or two inch pipe stand. The HFI is suitable for the severe sulfur processing environments and is corrosion resistant.

Features

- Accurate, continuous purge flow rate

- Insures long-term temperature measurement reliability

- Corrosion resistant, suitable for Sulfur Unit environment

- All stainless steel construction

- Two mounting options

- Simple, easy installation

Specifications

- Flow Range: 4 L/min to 38 L/min std

- Pressure Indicator: 2.5 in diameter, 0 psig to 60 psig (0 bar to 4.1 bar)

- Flow Control: Constant mass flow rate type

- Pressure Control Range: 2 psig to 50 psig (0.1 bar to 3.4 bar)

- Filter:5 μm sintered polypropylene

- Drain:Manual valve

- Meter body: Stainless steel

- Pressure Body: Stainless steel

- Connection Fittings: Stainless steel, 0.125 in FPT pipe or millimeter size tubing

- Faceplate and Pipe Clamps: Stainless steel

- Supply Pressure: 25 psig to 250 psig (1.7 bar to 17.2 bar)

- Supply Gas: Clean dry air or nitrogen

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation & testing packages (if required, refer to Additional Resources in the product catalog)