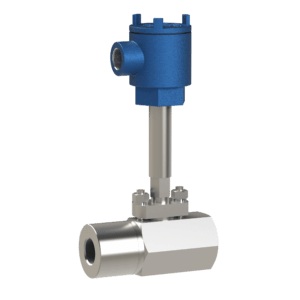

Flow Switch, Inline Body, Ultralow Flow, Adjustable Actuation

The Delta Controls Model 625 Flow Switch detects ultralow flows for 0.25 inch to 1.0 inch (6 mm to 25 mm) pipelines. Applications include flow protection, safety monitoring, purging for explosion proofing, as well as detection of additives, oiling, purging, etc with a low pressure drop at 35 times detected flow rate. It produces on/off switching actions at a preset rate of flow and is field adjustable.

The flowing fluid passes through the variable piston annulus and/or the adjustable bypass valve. Increasing differential pressure causes the piston to move and compress the range spring. When the piston magnet is carried to the switch magnet, the switch magnet attracts and the output snap switch actuates. The size of the bypass valve opening determines the flow rate switching point.

Features

- Detects ultralow flows for 0.25 inch to 1 inch pipelines

- Used for detection additives, oiling, purging, etc.

- Low pressure drop at 35 times detected flow rate

- Field adjustable

Specifications

- Style: Inline

- Type: Piston

- Temperature: -4 °F to +400 °F (-20 °C to +204 °C)

- Standard Pressure: ≤ +2000 psi (≤ +137.9 bar)

- Actuation: 0.04 gpm to 0.75 gpm (water) 0.18 scfm to 2.7 scfm (air)

- De-actuation: 0.03 gpm to 0.6 gpm (water) 0.15 scfm to 2.0 scfm (air)

- Accuracy: ≤ 10%

- Output: SPDT or DPDT, 5 A

- Wetted Material: 300 Stainless Steel, brass, nitrile, Teflon

- Housing Material: Stainless Steel, aluminum

- Threaded Process Connection: 0.5 in to 1 in FPT

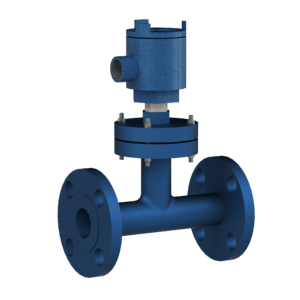

- Flanged Process Connection: 1 in

- Flange Rating: ≤ 150 lb

Certifications & Approvals

- Stainless Steel Housing Options Only: Third Party Listed by CSA NRTL/C (USA and Canada)

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)