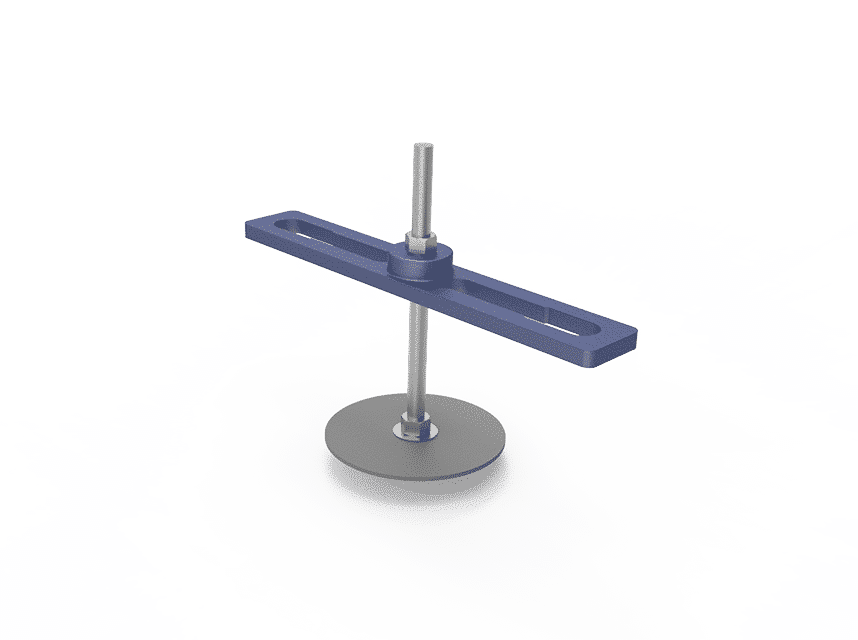

Refractory Stop

The Delta Controls Model HRS Refractory Stop prevents insulating castable refractory or mortar from entering the thermocouple nozzle during lining of the reactor. After the refractory has cured, the HRS is removed and the refractory is drilled using the Model HRG drilling system.

The castable surface must be flat, smooth, and even with the vessel shell’s interior surface for the HRW refractory thermowell to be positioned and supported correctly. The HRS is fitted with an adjustable seal plate that is positioned to be flush with the nozzle bottom when even with the inside surface of the vessel shell. Alternative methods, such as taping or troweling, are not as effective in creating a smooth and level surface.

Refractory systems using insulating brick in place of insulating castable do not require the HRS.

Features

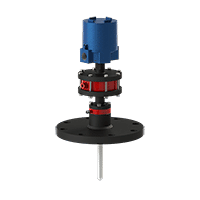

- Prevents castable refractory material from entering the mounting nozzle for Delta Controls Model HTP/HTX/HTV thermocouple

- Produces a smooth castable surface for Model HRW thermowell support collar

- Automatically centers in nozzle and is factory preset for nozzle inside height

Specifications

- Flange Sizes:4.0 in to 6.0 in

- Class:4 in Class 150 to 6 in Class 300

- Nozzle Inside Diameter: 3.4 in to 6.0 in (86 mm to 154 mm)

- Nozzle Height: As required

- Disc Size: As required

- Disc Insertion: As required ± 2.0 in (± 50 mm) adjustability

- Disc Material: Aluminum, PVC, plated steel

- Bar Material: Aluminum

Required Ordering Information

- Detailed model number

- Documentation & testing packages (if required, refer to Additional Resources in the product catalog)