Level, Flow and Temperature Solutions

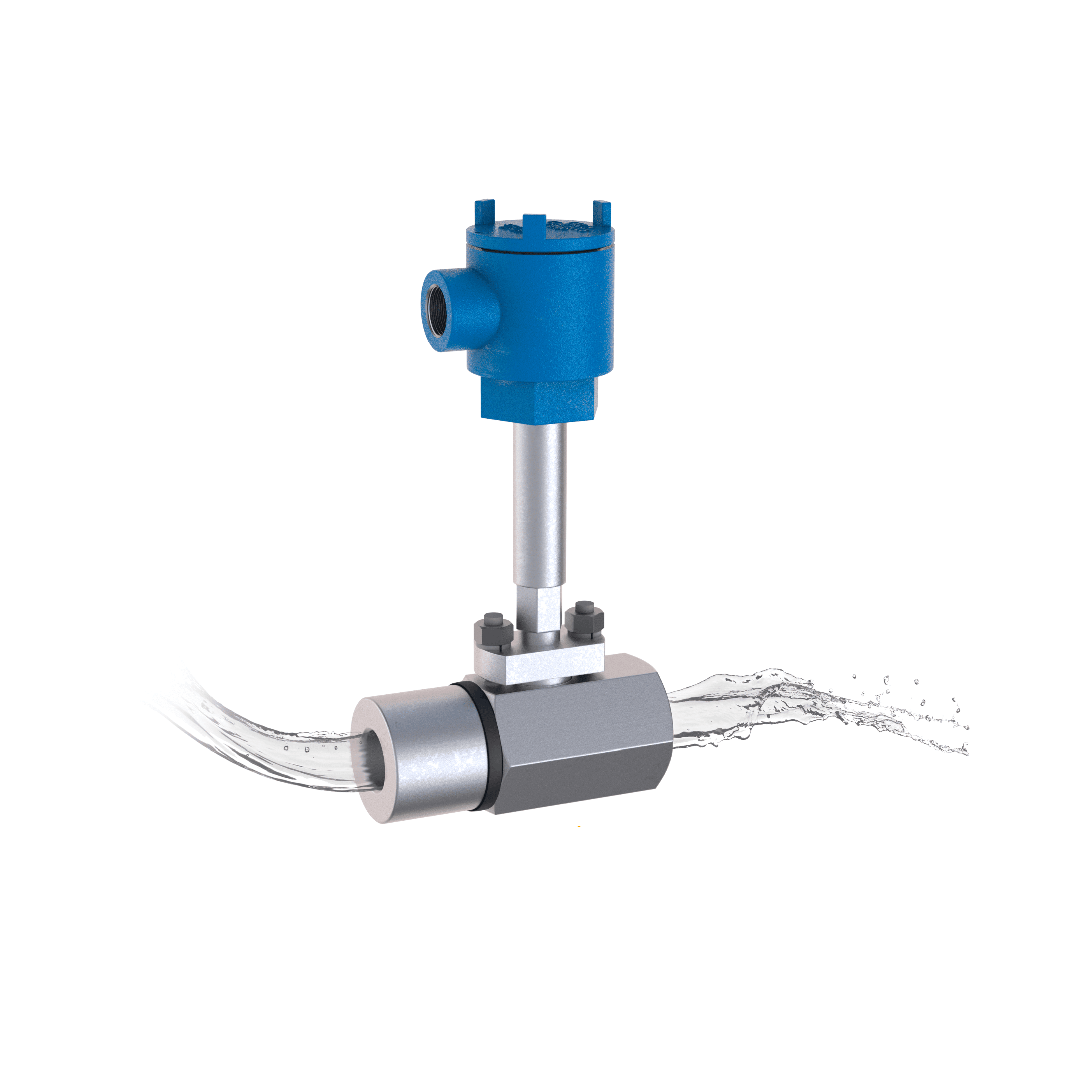

Delta offers three main product lines of level, flow, and temperature instrumentation, encompassing a variety of technologies including thermocouple, pyrometer, pressure, capacitance, mechanical, and more. All Delta products are manufactured to the extensive quality standards of our Louisiana-based factory.