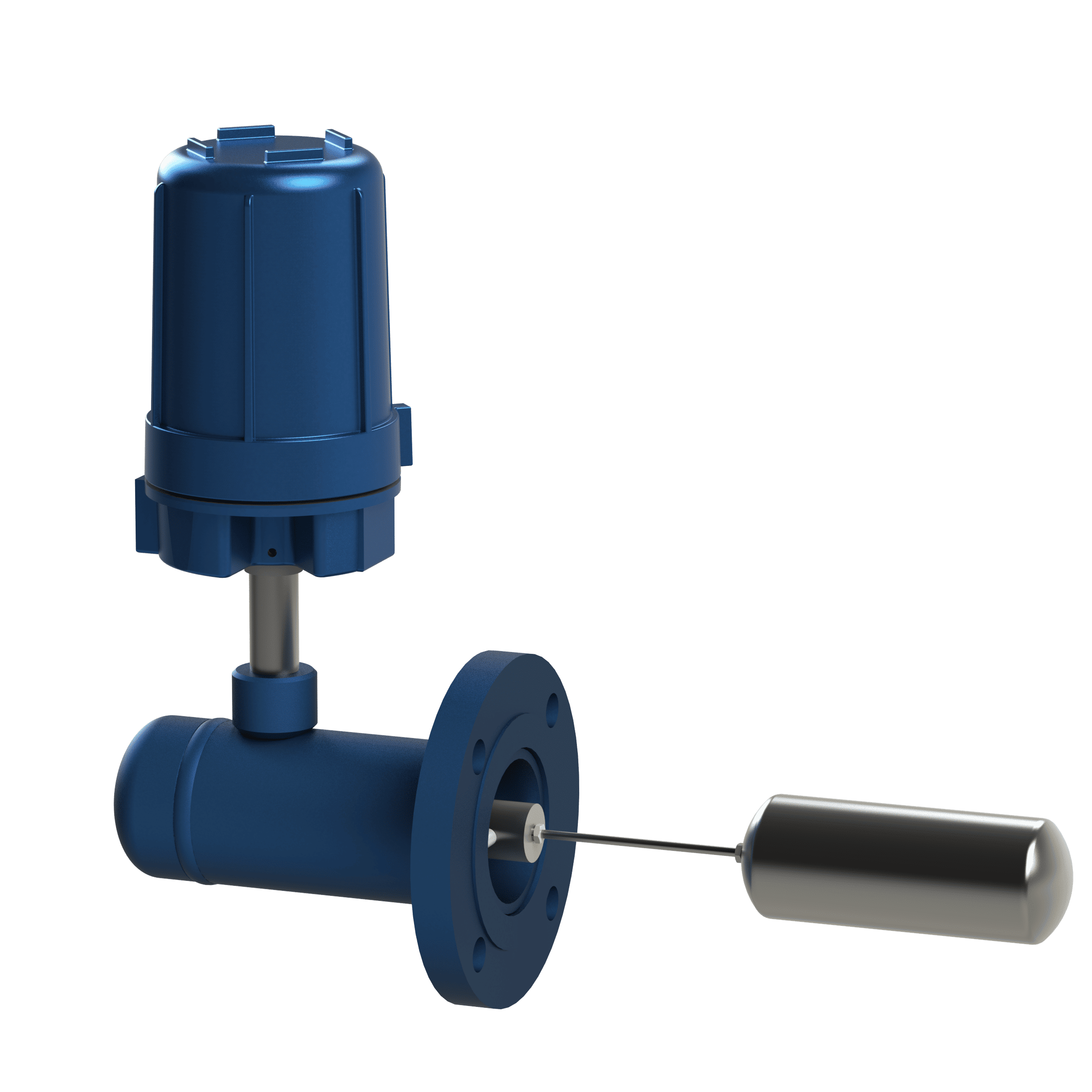

Float Switch, Side Inserted, Two Point

The Delta Controls Model 740 Float Switch provides two separate alarm points with up to an eight inch spacing between them. The spacing between the switch points is controlled by the length of the float insertion and the differential adjustment setting.

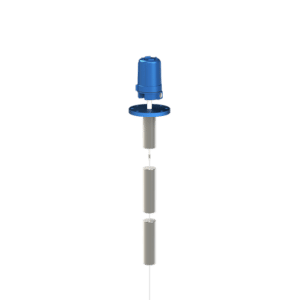

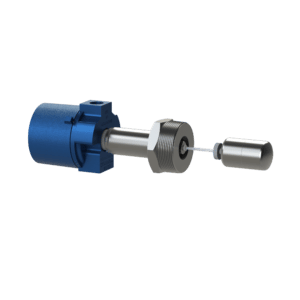

The 740 is located on the side of the vessel with the float extending into the vessel. The float moves with the surface of the liquid and is carried up and down as the liquid level varies. The attractor is coupled to the float by the linkage and also moves up and down as the level varies. The attractor is located inside of the barrier tube and contacts the process fluid. The switching stations are located on the outside of the barrier tube and are isolated from the process fluid. Each switch station contains a magnet whose magnetic lines of force penetrate the nonmagnetic barrier and are magnetically attracted to magnetic materials such as the attractor. The magnet is pulled in against the tube as the attractor moves up into its magnetic field. The magnet is connected to an output switch which actuates as the magnet is pulled in against the barrier tube.

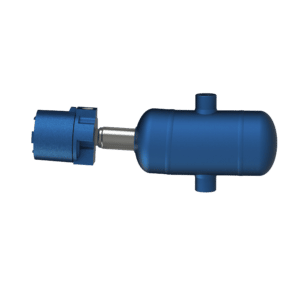

Options: The Model 740 Option D uses an adjustable differential device and a single switch station. The float moves down as the liquid level drops. This causes the attractor to be moved into the field of the switch station magnet; the magnet is pulled against the sealing tube and the switch is actuated. The switch stays activated until the liquid level rises significantly (an adjustable mount). The attractor is then pulled out of the field of the switch magnet and the switch deactivates. The amount of differential is controlled by the length of the float insertion and the setting of the differential device; up to 16 inch differential is possible. Typical applications include ‘Low’ alarm and ‘Low-Low’ shutdown for pump protection; control of a pump in a catch tank; and similar services.

Features

- Two alarm points

- Side inserted float switch

- Optional differential

- Barrel tube encased attractor

- Two switch actions occur as the elevation varies

Specifications

- Wetted Materials: 304 Stainless Steel, 316 Stainless Steel, carbon steel

- Switch Action: 2 points of alarm and/or differential

- Insertion (From Process Connection): 12 in to 48 in

- Specific Gravity: 0.50 to 2.40

- Temperature Range: -50 °F to +750 °F (-45 °C to +399 °C)

- Pressure Range: -15 psig to +2200 psig (-1 bar to +151.6 bar)

- Threaded Process Connection: 3.0 in to 4.0 in NPT

- Flanged Process Connection: 3.0 in to 8.0 in

- Flange Rating: ≤ 300 lb ANSI flanges or Grayloc® hub DIN or JIS equivalents

Certifications & Approvals

- Third Party Listed by CSA NRTL/C (USA and Canada) Class I, Division 1, Groups B, C and D; Class II, Division 1, Groups E, F and G; Class III, Division 1 Class I, Zone 1, Ex d IIB+H2 Class I, Zone 1, AEx d IIB+H2

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)

- Process fluid or material name*

- Process fluid or material specific gravity

- Maximum process temperature

- Maximum process pressure