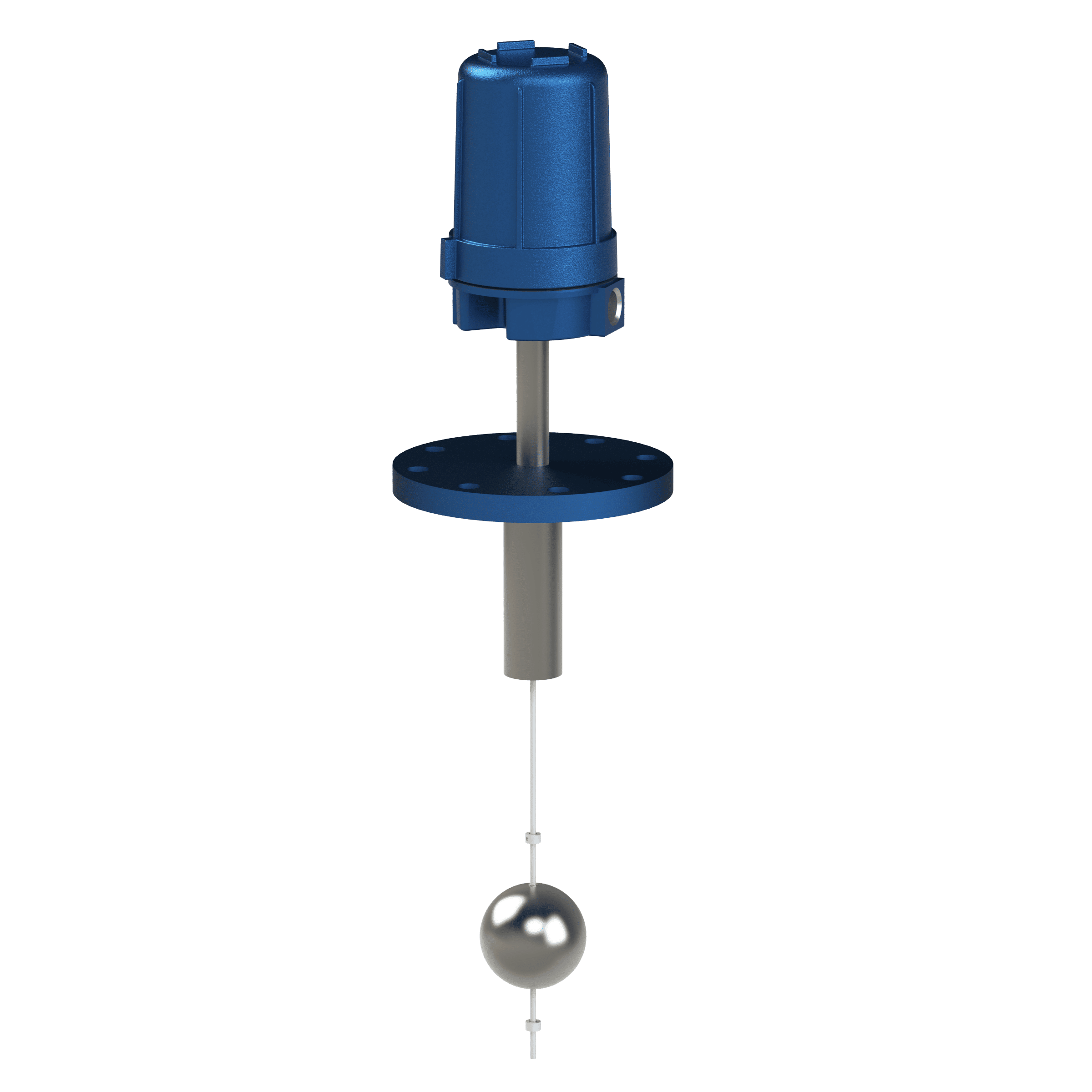

Float Switch, Top Inserted, Two Point, Wide Separation

The Model 711 Float Switch provides two point alarms with 6 to 65 inches of spacing between the two switching points. The switching points may be easily changed in the field by repositioning the stops. The normal application would be for high/low alarm. Note that the liquid should not leave significant coatings or deposits on the rod.

A float is supported by the liquid’s surface and freely travels up and down the stroke rod. The horizontal position is maintained by the stroke rod when the liquid level varies. The attractor is supported at the midpoint of its travel by a spring. When the level increases, the float lifts until it contacts the upper stop. The stroke rod is then lifted and the attractor is pulled into the station’s magnetic field. The magnet pulls in against the outside of the sealing tube and the switch activates. A falling level drops the float away from the upper stop, the attractor moves down, and the switch deactivates.

Similarly, a falling level carries the float down until it contacts the lower stop. The weight of the float pushes the rod down, lowers the attractor to be in front of the magnet, and the lower switch actuates. Once the float rises above the stop, the spring pulls the attractor from the lower switch station’s magnetic field and deactuates.

The 711 functions in many applications that would otherwise require the use of two separate conventional float switches. This results in cost savings for both the equipment and the decreased installation required.

Model 711D, Differential Option, is a single switching station normally used to control pumping action in a process vessel or storage tank. The station activates when the float rises to the upper stop and lifts the stroke rod attractor into the station’s magnetic field. The station stays activated until the float moves against the lower stop. The stroke rod attractor is pulled from the magnetic field and the switch station deactivates. It remains deactivated until the float contacts the upper stop.

Features

- Two alarm points

- Horizontal position maintained by stroke rod

- High and low alarm

- Liquid supported float

- Does the job of two conventional float switches

Specifications

- Wetted Materials: 316 Stainless Steel, carbon steel

- Insertion (Below Process Connection): ≤ 10 ft

- Switch Action: 2 alarm points and/or differential

- Specific Gravity: 0.35 to 2.40

- Temperature Range:-150 °F to +750 °F (-101 °C to +399 °C)

- Pressure : -15 psig to +1200 psig (-1.0 bar to +82.7 bar)

- Threaded Process Connection:1.0 in to 3.0 in NPT

- Flanged Process Connection:2.0 in to 8.0 in

- Flange Rating: ≤ 300 lb ANSI flanges, or Grayloc® hub, DIN, JIS equivalents

Certifications & Approvals

- Third Party Listed by CSA NRTL/C (USA and Canada) Class I, Division 1, Groups B, C and D; Class II, Division 1, Groups E, F and G; Class III, Division 1 Class I, Zone 1, Ex d IIB+H2 Class I, Zone 1, AEx d IIB+H2

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)

- Process fluid or material name*

- Process fluid or material specific gravity

- Maximum process temperature

- Maximum process pressure