Pressure Series

Pressure Transmitters for Water, Wastewater, and More.

35+ Years of Dependable Service Dedicated Commitment to Delivery Engineered for Demanding Applications

The Delta Controls pressure transmitters offer a heavy duty engineered design for wide-ranging applications; including those with agitation, corrosive materials, sanitary materials, and atmospheric pressure. Each can be specifically configured for the unique needs of each application offering custom cable lengths, process connections, materials of construction, and numerous options. Due to the critical role level transmitters play in many modern processes, Delta is committed to quick shipments to ensure smooth operations.

Showing all 10 results

-

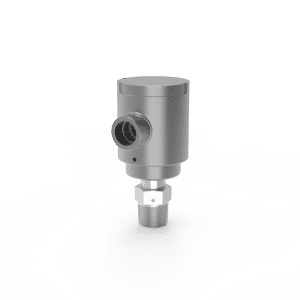

Model 551

Pressure Transmitter, Compact Size

Learn More » -

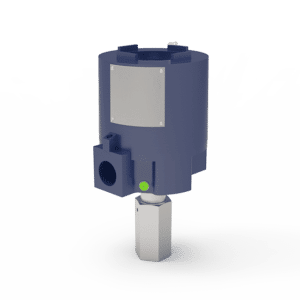

Model 552

Pressure Transmitter, Modular Electronics

Learn More » -

Model 562

Pressure Transmitter, Cable Suspended, Pipe Supported

Learn More » -

Model 563

Pressure Transmitter, Modular Electronics, Extended Face

Learn More » -

Model 565

Pressure Transmitter, Large Diaphragm, Integral Electronics

Learn More » -

Model 566

Pressure Transmitter, Large Diaphragm, Remote Electronics

Learn More » -

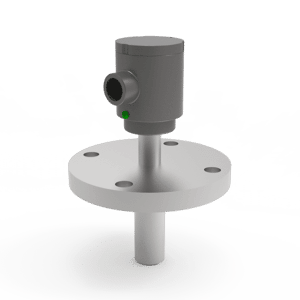

Model 571

Pressure Transmitter, Compact Size, Sanitary Service

Learn More » -

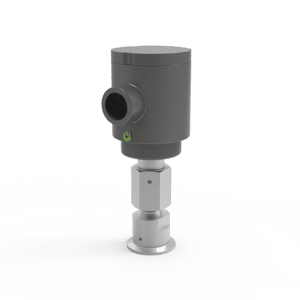

Model 572

Pressure Transmitter, Modular Electronics, Sanitary Service

Learn More » -

Model 591

Pressure Transmitter, Cable Suspended, Integral Electronics

Learn More » -

Model 592

Pressure Transmitter, Cable Suspended, Remote Electronics

Learn More »