Capacitance Series

A Capacitance Level Solution for Every Application.

With 15+ probe style offerings and service to 1500 psig and 850 °F, Delta has a capacitance solution for the more unique and demanding level applications of today’s industries. Delta’s probes are procured in a variety of materials, including carbon steel, stainless steel, monel, Hastelloy®, Teflon™, ceramic, and others upon request. With 50+ years of expertise in capacitance technology, Delta’s engineered products provide reliable and accurate operation in critical applications.

Showing all 16 results

-

Model 105

Capacitance Level Switch, Optional Remote Mount, DPDT

Learn More » -

Model 107

Capacitance Level Switch, Multipoint, Two or Four DPDT Relays

Learn More » -

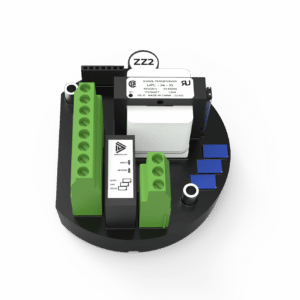

Model 173

Capacitance Level Transmitter, Loop Powered, Digital Circuitry

Learn More » -

Model IPT

Capacitance Interface Transmitter, Refinery Desalter

Learn More » -

Model P21

Capacitance Probe, Tubular Ground

Learn More » -

Model P25

Capacitance Probe, High Temperature and Pressure Service, Tubular Ground

Learn More » -

Model P26

Capacitance Probe, High Temperature and Pressure Service, Slotted Tubular Ground for Interface Service

Learn More » -

Model P31

Capacitance Probe, External Cage, Vertical

Learn More » -

Model P51

Capacitance Probe, Solid Rod, General Purpose Use

Learn More » -

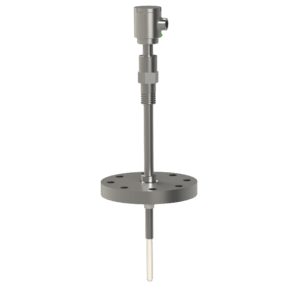

Model P52

Capacitance Probe, Heavy Duty

Learn More » -

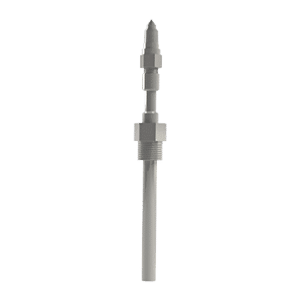

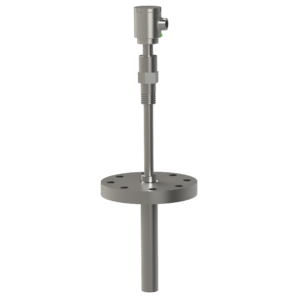

Model P55

Capacitance Probe, High Temperature and Pressure

Learn More » -

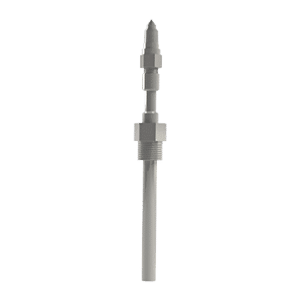

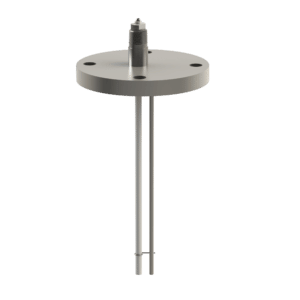

Model P56

Capacitance Probe, High Temperature and Pressure, Tubular Ground

Learn More » -

Model P57

Capacitance Probe, Parallel Ground

Learn More » -

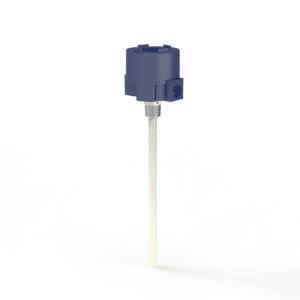

Model P71

Capacitance Probe, Flexible Cable

Learn More » -

Model P72

Capacitance Probe, Flexible Cable, Parallel Ground

Learn More » -

Model P91

Capacitance Probe, Floating Probe for Oil Skimmer

Learn More »