Capacitance Interface Transmitter, Refinery Desalter

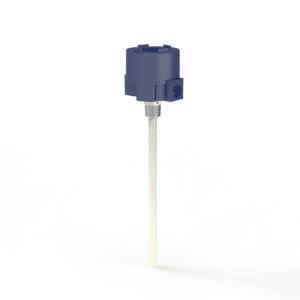

The Delta Controls Model IPT senses interface position by measuring energy transferred from the probe into the surrounding material. The energy transfer is at a minimum when the probe is covered with crude oil and at a maximum when it is covered with water. The Model IPT transmitter is calibrated by entering two interface elevation points. The transmitter then automatically calculates a curve through those points. The result is a 4-20 mA output signal that is proportional to the elevation of the interface position. This information is displayed on the integral LCD display.

Measurement of the interface position between water/oil in refinery desalters has commonly been attempted through the use of analog type capacitance level transmitters. Unfortunately, the measuring probe of these devices quickly becomes coated with carbon, water emulsions, and other material. This coating and buildup creates interface position errors and eventually renders the output signal meaningless. Probe cleaning is effective, but is not practical because the desalter must be shut down before the probe can be removed.

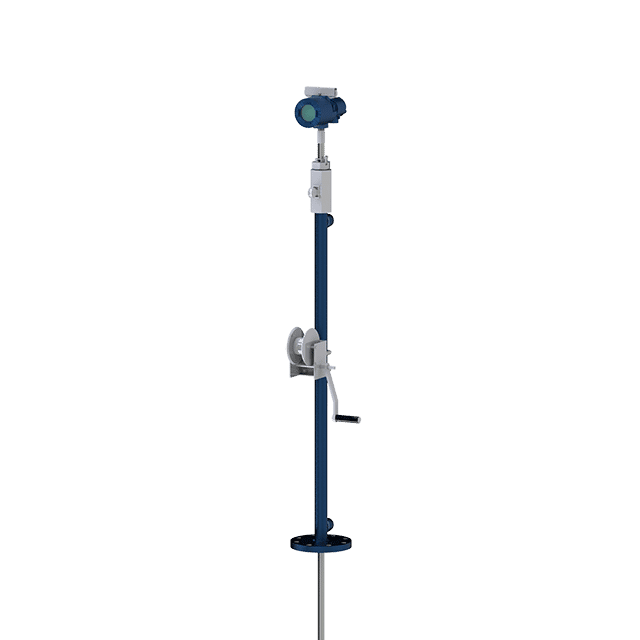

The Model IPT is a specially designed probe type interface transmitter that does not require shutdown of the desalter. The sensing probe design is less sensitive to buildup. It also permits extraction,cleaning of the probe and reinsertion without disturbing the operation of the desalter unit. The IPT design allows the needed infrequent cleaning of the probe to be easily and safely performed.

The Model IPT assembly is mounted on top of a desalter isolation valve, which allows its removal without depressurizing the desalter. The sensing probe is withdrawn into a chamber located above the block valve whenever access to the probe is desired. The valve is then closed beneath it, permitting depressurization of only the withdrawal chamber for cleaning. If required, the entire Model IPT can be completely removed without disturbing the desalter.

Features

- Continuous interface position signal

- Up to 6 feet (1800 mm) measurement range

- Extract/Remove sensor or clean in place

- Pushbutton calibration

- 2-wire 4-20 mA interface position signal

Specifications

- Output (Isolated): 4-20 mA loop signal

- Loop Impedance (Max): 500 Ω @ 24 DCV; 900 Ω @ 30 DCV

- Display: LCD Screen, 2 line, 8 character, alphanumeric

- Calibration Entry: 4 pushbutton switches

- Voltage Requirements: 12 DCV to 30 DCV Loop Power

- Ambient Temperature Range: -20 °F to +175 °F (-30 °C to 80 °C)

- Best Display Readability Range: +30 °F to +125 °F (-1 °C to +50 °C)

- Process Connection: 3 in min

- Flanged: 3.0 in to 6.0 in

- Flange Rating: ≤ 300 lb ANSI or equivalent DIN, JIS flanges

- Available Wetted Materials: 316 Stainless Steel, carbon steel, PTFE

- Insertion and other Dimensions: As required by desalter design

- Housing: Class 1, Division 1, Groups BCD, EFG explosion-proof optional

- Housing Material: Aluminum, stainless steel

Certifications & Approvals

- HART® Protocol compliant

- Explosion-proof Housing Option: Third Party Listed by CSA NRTL/C (USA and Canada) Class I, Groups B, C, and D; Class II, Groups E, F and G; Class III; Encl 4X

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)

- Dimensional detail worksheet (Document No. 00-IPT05)