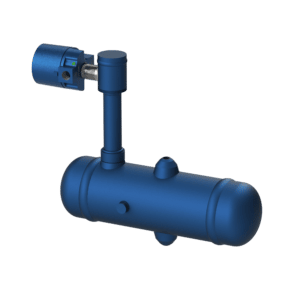

Float Switch, External Cage, Vertical

The Delta Controls Model 760 Float Switch is an industry standard. Thousands of units are providing continuous general purpose level detection service with highly reliable monitoring of liquid levels and interfaces.

The 760 external cage mounted float actuated switches are used to provide alarm functions. These actions are produced in response to a float position as it rides up and down the surface of the process liquid level or interface dividing line. All units are equipped with a guide bushing at the lower end of the stroke rod. This feature keeps the float and attractor mechanism centered in the cage and prevents the float from dragging on the cage wall. Failures due to dragging, sideways binding, and bent rods have historically been problems with older vertically rising float designs.

The 760 is available with a flanged external cage, which allows access to the float and internal parts for inspection and maintenance. The flange is an ANSI design and usually carries the same pressure rating as the element assembly with higher pressure ratings available. It is available with standard or special connection configurations. These include side/ bottom, side/side, and side/side/bottom drain. All connections are available either threaded, socket weld, or flanged.

The float inside the cage rests on the surface of the liquid and rides up and down with as the level changes. An attractor is attached to the float and also moves with the liquid level. When the level rises, the attractor is move up into the field of the switch station magnet. The magnet is free to move and is pulled in against the side of the nonmagnetic sealing tube. The output switch is actuated by the movement of the magnet. Similarly, when the liquid level falls, the attractor is pulled out of the magnet. The return spring pulls the magnet back to its original position and the output switch is deactuated.

Features

- Recognized worldwide

- One alarm point

- External cage float mounted outside of vessel

- Available in threaded, socket welded, or flanged process connections

- Simple, yet robust design

Specifications

- Wetted Materials: 304 Stainless Steel, 316 Stainless Steel, carbon steel

- Switch Action: Single point alarm

- Specific Gravity: 0.40 to 2.40

- Temperature: -100 °F to +800 °F (-73 °C to +427 °C)

- Pressure: -15 psig to 20 000 psig (-1 bar to +1400 bar)

- Optional Drain: 1.0 in NPT

- Orientation: Side/Bottom, Side/Side, Side/Side/Drain

- Socket Welded Process Connection:1.0 in

- Threaded Process Connection:1.0 in FPT to 2.0 FPT

- Flanged Process Connection:1.0 in to 2.0 in

- Flange Rating: ≤ 2500 lb ANSI flanges or Greyloc® hub DIN or JIS equivalents

Certifications & Approvals

- Third Party Listed by CSA NRTL/C (USA and Canada) Class I, Division 1, Groups B, C and D; Class II, Division 1, Groups E, F and G; Class III, Division 1 Class I, Zone 1, Ex d IIB+H2 Class I, Zone 1, AEx d IIB+H2

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)

- Process fluid or material name*

- Process fluid or material specific gravity

- Maximum process temperature

- Maximum process pressure

- Upper and lower materials required for interface service